Automotive Manufacturing

Driving innovation

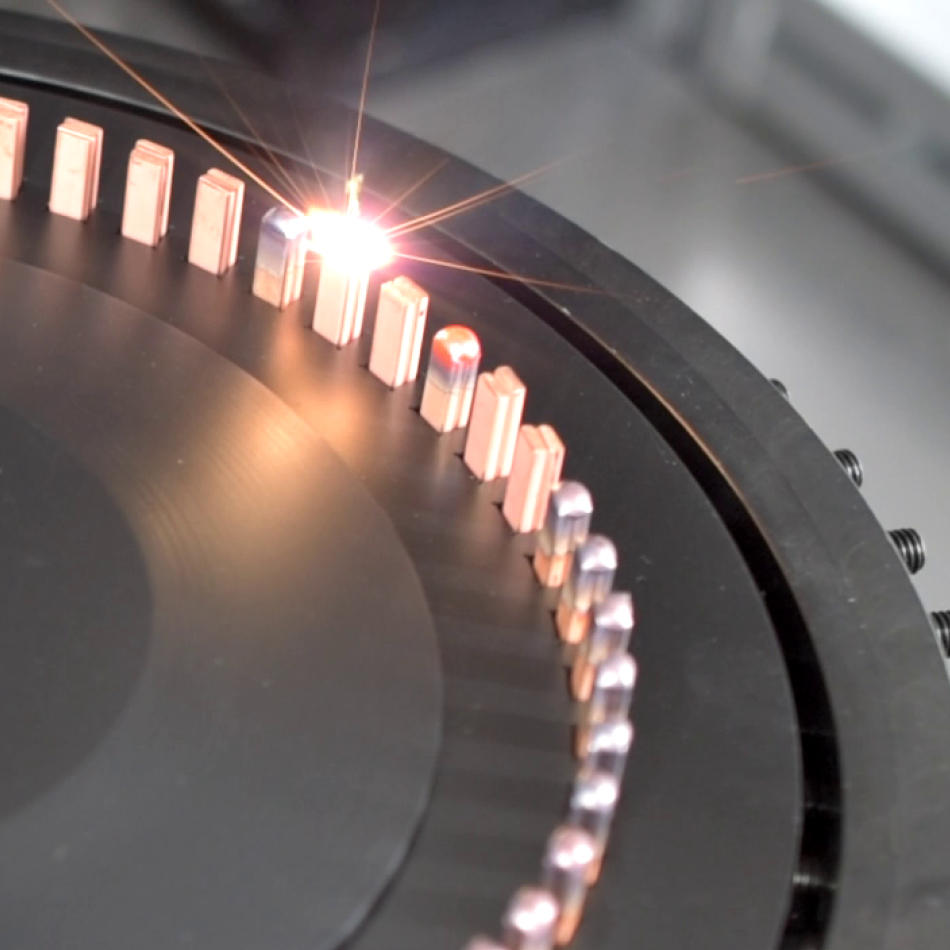

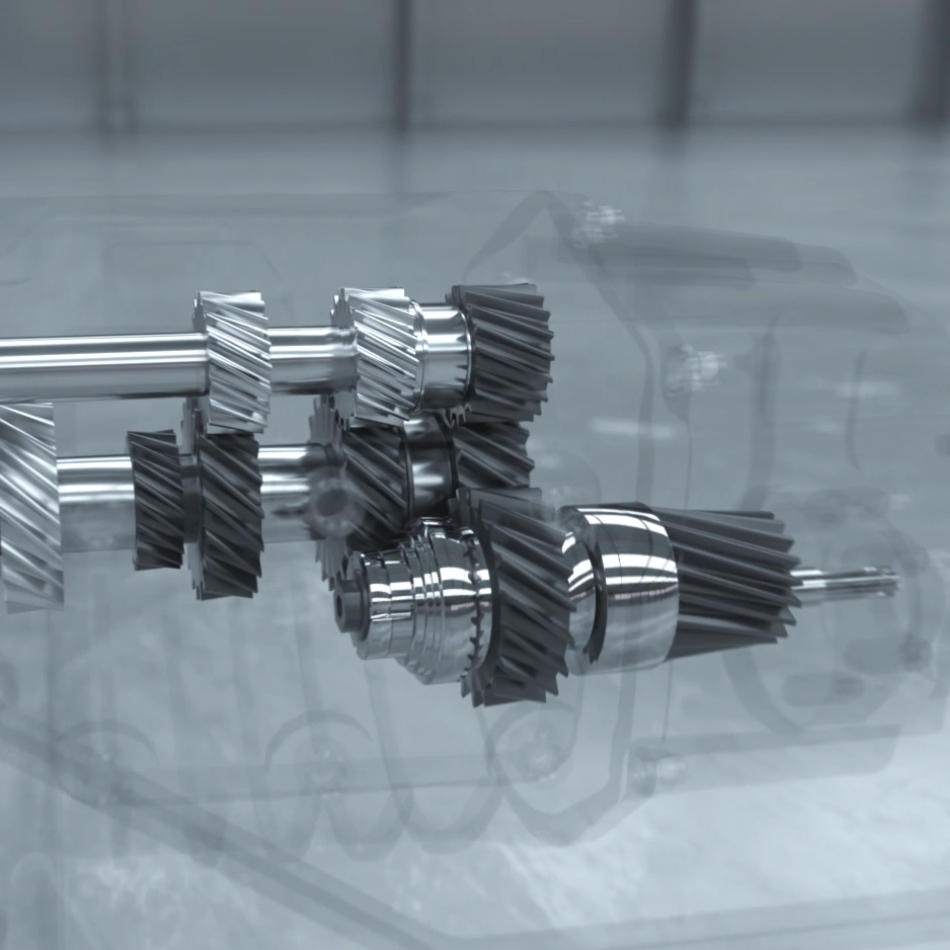

Meet EV production challenges with cutting-edge technology that improves performance and reliability, and also lowers costs.

Featured Blog

SiC power electronics improve EVs

Discover why SiC power electronics are in demand for improving EV performance.

Ready to Get Started?

Share your contact info and a specialist will reach out.

By providing your information and clicking ‘Subscribe’, you opt-in to receiving periodic email marketing communications from Coherent Corp. and understand that your personal data will be processed in accordance with our Privacy Policy and that our Terms apply. You may opt-out of marketing emails sent by us at any time by clicking the unsubscribe link in any marketing email you receive.

Shop Coherent

Online shopping for lasers, optical fibers, power meters and sensors, accessories, and much more on Coherent online has never been easier.