Laser Machines and Systems

WaferLase II

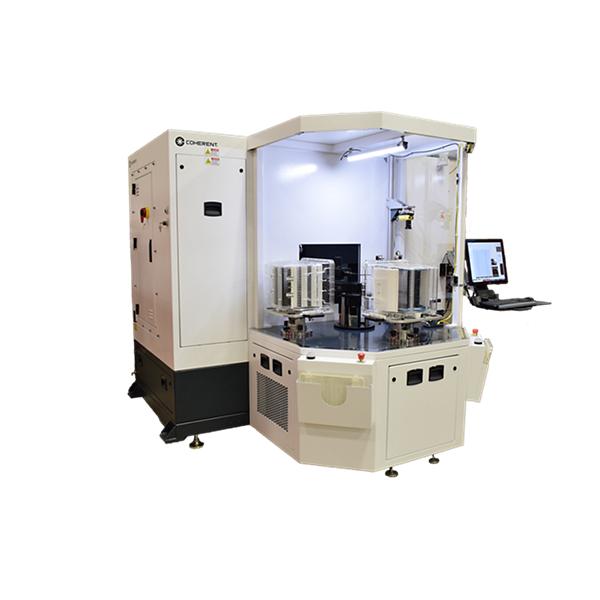

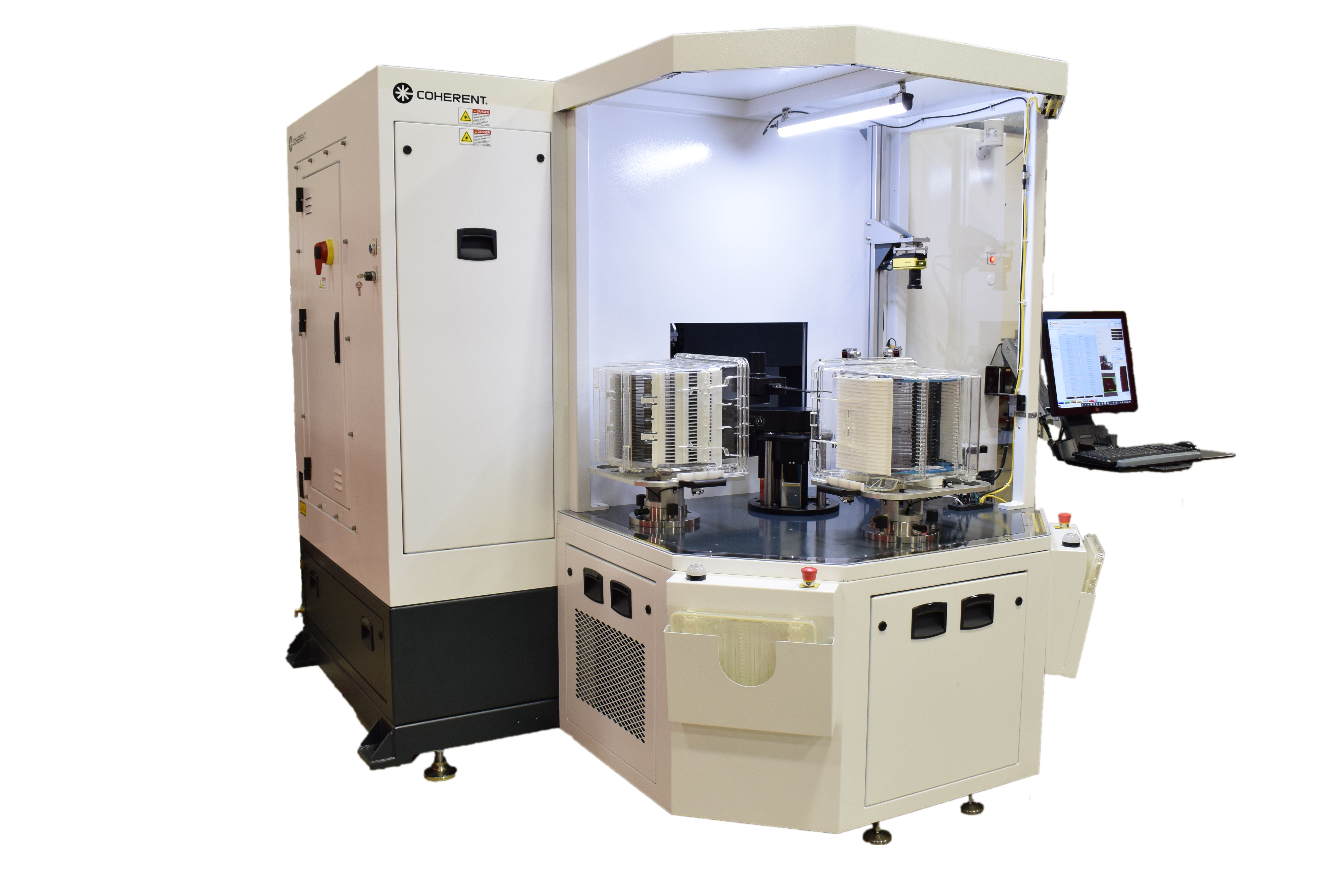

Perform high-speed silicon wafer etching, marking, and glass scribing for NGS Flow Cell production with automated tools that deliver high precision with minimal heat damage.

WaferLase systems combine robotic part handling, automated part alignment, a laser source, beam delivery optics, and control and interface software. System components are mounted on a granite base within a welded steel frame for maximum stability.

By providing your information and clicking ‘Subscribe’, you opt-in to receiving periodic email marketing communications from Coherent Corp. and understand that your personal data will be processed in accordance with our Privacy Policy and that our Terms apply. You may opt-out of marketing emails sent by us at any time by clicking the unsubscribe link in any marketing email you receive.

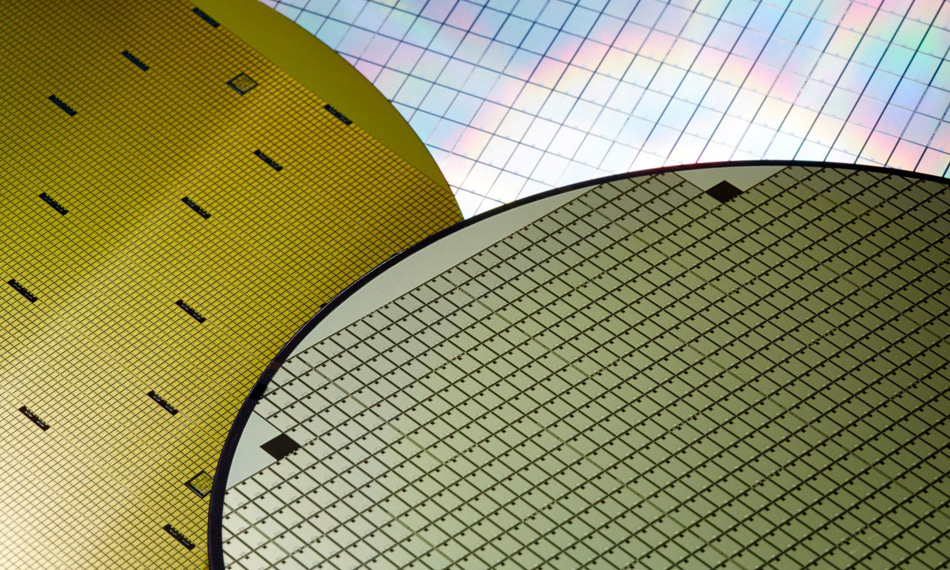

Semiconductor Wafer Marking and Glass Scribing

Select the laser source, part transport, and other automation options to configure a WaferLase processing system that is right for your application and budget.

Product Specifications

Parameter |

Details |

Dimensions (L x W x H) |

2560 mm x 2315 mm x 2084 mm |

Laser Source |

Ultrashort Pulse Laser |

Axis Travel X/Y/Z |

450 mm x 450 mm x 150 mm |

Axis Speed |

up to 1000 mm/sec |

Featured Blog

WaferLase II Streamlines NGS Flow Cell Production

The new Coherent WaferLase II automated glass cutting systems combines automation with the proprietary SmartCleave technology for an environmentally friendly, low-cost production solution for Next Generation Sequencing (NGS) Flow Cells.